Guoguang has produced various cutlery moulds for various countries around the world. Cutlery products are roughly classified into three types from the perspective of use: aviation cutlery, household cutlery, and military cutlery. From the appearance of the product, it can be divided into ordinary cutlery and folding cutlery. Different products are equipped with different cutlery on different occasions. For example, the plastic cutlery used in restaurants are all ordinary cutlery, and the cutlery used on some foods is generally folded, which does not take up space and is convenient for packaging. Different cutlery moulds have different processing techniques.

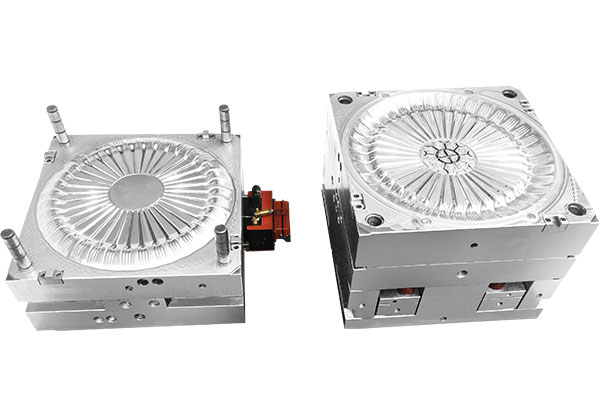

Cutlery’s plastic material generally has two kinds of PP\PS. Different plastic materials have different choices of steel materials for moulds. Cutlery moulds generally choose steel materials such as H13, S136, 2344, 2316, and quenching materials. Because cutlery products are fast-moving consumer goods, the moulds are generally multi-cavity, and the mould shape is designed to be square or round. Use point gate method. The hot runner adopts full hot runner or semi-hot runner. If the mould is designed to be square, then semi-hot runner can be used, and the mould is made into a built-in type. Guoguang cutlery mould processing technology includes high-speed precision carving, high-speed milling and so on. Ordinary cutlery moulds are generally two-part moulds, while folded cutlery moulds have more sliders on the basis of two-part moulds. Therefore, folding cutlery moulds is more difficult than ordinary cutlery moulds.

Guoguang is not only specialized in cutlery moulds, but also very skilled in thin wall moulds such as thin wall food container mould.

The upper die of the disposable tableware mold includes a concave die, an upper die seat, a concave die piston, a demoulding piston rod and a demoulding template. The lower end of the demoulding piston rod is covered with an upper gasket, the lower end of the concave die and the lower end of the gasket is covered with an upper semicircular groove, the outer cover of the thin washer is provided with an active ring, the active ring is covered with an upper blade, and the outer surface of the thin washer is provided with a circular chamfering 1, The outer part of the middle of the thin washer is provided with a circle of circular chamfer 2, and the inner part of the active ring is provided with a circle of circular chamfer 3, which is located below the circular chamfer.

Post time: Jul-22-2022